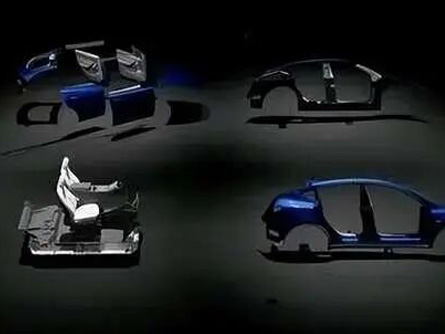

In 1913, Ford revolutionized automotive manufacturing with the assembly line; in 2023, Tesla dismantled the assembly line with the "Unboxed Process"! They split the vehicle into 6 major modules (chassis, battery compartment, door system, etc.), assembling them in parallel like building blocks – a Model Y is integrated and rolls off the line in just 45 seconds, speeding up the process dozens of times compared to traditional production lines. Recently, Tesla CEO Elon Musk even stated confidently that this technology will achieve a production rate of one car every 5 seconds.

The Unboxed Process brings fundamental breakthroughs to the industry: modular parallel processing aims to reduce the cycle time per vehicle bay to 5 seconds, significantly reduces factory footprint, lowers painting costs, and can reduce final assembly costs by 30%-50%, paving the way for affordable electric vehicles.

Tesla's "Unboxed Process" divides the vehicle into 6 major modules. Image source: Internet

Why is Welding Being Abandoned?

Structural Adhesives are the Only Solution

When Tesla used a mix of stainless steel and aluminum alloy on the Cybertruck, traditional welding hit a "dead end": the different thermal expansion coefficients of dissimilar materials cause deformation and cracking during welding; bolted connections increase body weight, contradicting the lightweight requirements of electric vehicles; structural adhesives became the only solution.

Image source: Internet

Gluing a Car Together? Is it Reliable?

Modern Structural Adhesives' Special Curing and Toughening Systems

Today's structural adhesives are more powerful than you might think. The bulk strength of modern structural adhesives can easily exceed 30 MPa. For steel-to-steel bonds, tensile strength exceeds 30 MPa, and shear strength exceeds 18 MPa. The reason structural adhesives possess such ultra-high strength lies in the special curing and toughening systems added to the adhesive, forming a three-dimensional network skeleton far stronger than steel. Two-component synergistic curing creates a dense cross-linked network. The adhesive penetrates the material surface, into micron-level concave-convex features, forming a firm physical interlock after curing.

Image source: Internet

KLEBER's Answer

Structural Adhesive Solutions Born for the "Unboxed Process"

KLEBER offers a complete solution for the new era of automotive Unboxed Process manufacturing: High-Strength Room-Temperature Curing Body Structural Adhesive series; Impact-Resistant High-Strength Room-Temperature Curing Body Structural Adhesive series; Room-Temperature Curing Structural Adhesive series for Non-Metallic Materials. Addressing industry pain points, it eliminates the need for "high-temperature baking" – traditional epoxy adhesives require 160°C baking for 60 minutes, consuming high energy and constraining production line rhythm.

The KLEBER structural adhesive series achieves room-temperature curing, initial setting in 10 minutes, greatly improving production efficiency; stable performance in environments from -40°C to 150°C; 0.1mm level precision application ensures modules fit tightly, and requires no additional electrophoretic/plating anti-corrosion processes.

It abandons the traditional process requiring 160℃ high temperature and 60-minute baking for epoxy structural adhesives. Initial setting is achieved in just 10 minutes, significantly improving energy efficiency and production efficiency. Performance remains stable in environments from -40℃ to 150℃.

Achieves 0.1mm level precision coating. Ensures modules fit tightly and requires no additional electrophoretic/plating anti-corrosion processes.

The product solutions debuted at the Detroit Battery Show, which concluded early this October.

KLEBER has launched a full set of complete structural adhesive solutions for the automotive Unboxed Process.

As Tesla breaks with a century of tradition using modularization, structural adhesives have been upgraded from auxiliary materials to a core process. Without the sparks of welding, and bidding farewell to the energy consumption of high-temperature baking, cars are precisely joined at room temperature, driving towards a lighter, stronger, and more sustainable future.